About Us

Mekong

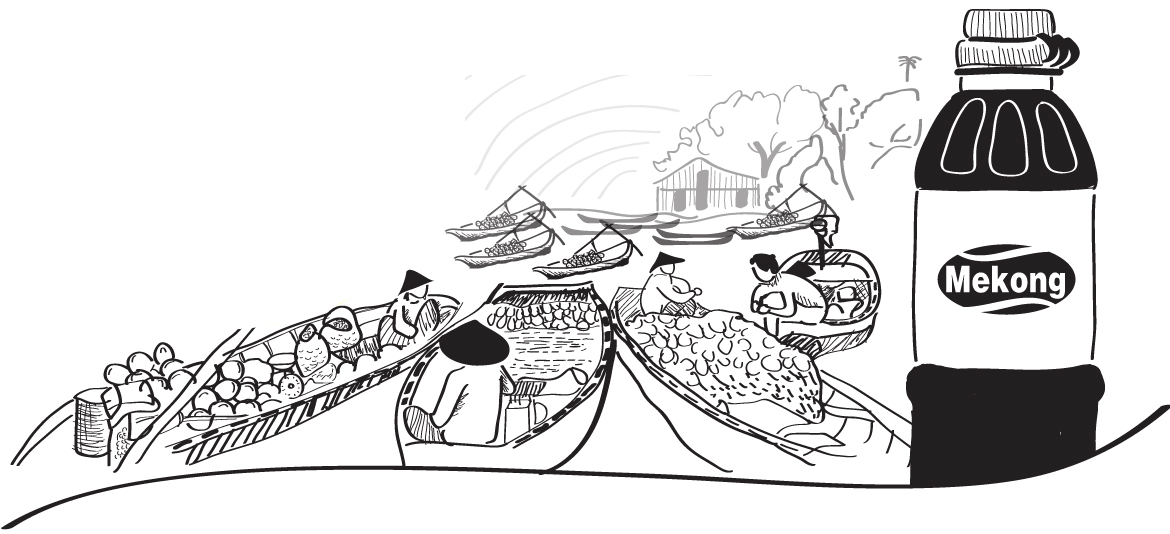

Mekong as a brand name is a constant reminder of our roots and origin– the Mekong Delta. Given the economy dynamics in the early years, Mekong is our founder's vision to sustain the company's growth and expansion in both domestic and global landscape. Just as the Mekong River nourishes the provinces along the delta, fostering prosperity, Mekong Sauce carries the mission in enriching family's connection through the joy of shared meals– honoring the abundance of culture and traditions.

An enterprise with decades of experience in operational management and production of condiments and seasonings. Since 2005, we have expanded our production capacity by establishing a new manufacturing factory spanning over 20,000 square meters in Long An, equipped with modern facilities. Technological processes are strictly monitored in accordance with health standards set by the Ministry of Health to ensure that the products delivered to customers always meet two fundamental criteria - quality and safety.

Mekong Sauce has been recognized for over 15 years as a provider of High-Quality Vietnamese Goods, operations processes are HACCP and U.S. FDA certified. Partners with global clients in the USA, Russia, Australia, Cambodia, Georgia, Belarus, Azerbaijan, South Korea, and Taiwan.

Mekong Sauce has been recognized for over 15 years as a provider of High-Quality Vietnamese Goods, operations processes are HACCP and U.S. FDA certified. Partners with global clients in the USA, Russia, Australia, Cambodia, Georgia, Belarus, Azerbaijan, South Korea, and Taiwan.

ENRICHING CULTURAL VALUES THROUGH TRADITIONAL VIETNAMESE CUISINE

PERFECTLY CATERING TO CONSUMERS' TASTE AND DEMAND